Success Story

UL864 Ethernet Switch Used With Siemens Building Technologies' APOGEE™ Software

Headquartered in Buffalo Grove, Illinois, Siemens Building Technologies is a leading supplier of products, services and solutions for fire alarm and life safety protection, as well as building automation and security.

Recently, Siemens began a project to offer their customers stronger integration between the company's building automation and fire safety systems. Siemens planned to enhance the versatile APOGEE™ Insight building automation software to allow facility operators to monitor and control their automation and life safety systems from a single workstation platform, as well as share information between those building systems.

"There's an advantage to having this capability," says Tom Rule, Product Manager for Siemens. "Using an integrated system, facility managers can gain a clear picture of the status of each subsystem within the facility. This allows them to provide a greater environment of safety, and enhance the productivity of their workforce by using Insight Life Safety workstations that carry UL Listings for fire, security, and critical process management applications. In addition, we are able to retrieve diagnostic information from reports and to configure the system to automatically initiate control sequences between building systems."

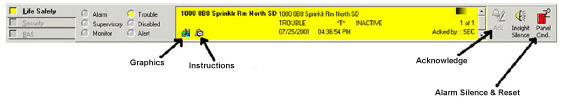

With the new system, the Alarm Bar application would enable an operator to view the current status of the fire, security, and building automation systems. From the Alarm Bar, operators with proper permissions would have the ability to acknowledge events and issue commands to the system.

Siemens chose Ethernet to provide the systems's communications. A portion of the project required UL 864 Recognition on workstation components for use in fireprotective signaling systems. All components, including workstations, monitors, and Ethernet switches used for communications between workstations, had to pass stringent hardware tests in order to acquire a UL Listing on the system. UL 864 Recognition on the Ethernet switches is required to meet the NFPA 72 code requirements that any communications path used for transmitting critical life safety data be listed for fire-protective signaling use. In the fire alarm industry that communication path is known as the Signaling Line Circuit.

"Only if every component from the smoke detector to the workstation used for monitoring the system, including Ethernet switches, is UL Recognized for fireprotective signaling use, can the entire system be considered UL Listed," explains Rule. "If any component on the signaling line circuit is not Recognized, then the Listing for the entire system is lost."

For isolation purposes, every networked Insight workstation that is listed for fire-protective signaling use must be connected to the Ethernet network through one of these special switches. Switches were employed because they can extend network distance beyond a single collision domain compared to repeating hubs while increasing performance. Performance is critical to ensure that emergency messages are delivered as quickly as possible.

In order to allow Ethernet switches to be powered from the fire alarm panel, with its inherent battery backup power, Siemens chose Contemporary Controls' EIS Ethernet Interconnect Switch Series, which is a UL 864 Recognized Component. The UL recognized component mark is rarely seen by the customer, but is often part of a larger end-product that is UL Listed by the fire alarm system supplier. For an end-product to be UL Listed, the product is tested by UL to determine if it meets the requirements established by UL's published Standards of Safety. A UL recognized component has already been evaluated and tested in accordance with UL's component safety standards, streamlining the qualification process for the end-product.

By having the fire alarm system supplier specifying a Contemporary Controls' EIS Ethernet switch to be used within the system, the supplier is not required to perform additional testing on this component. Several fire alarm and security firms have already specified the EIS series as part of their system thereby improving their time-to-market.

Components that bear the UL Recognized Component mark are separately covered under UL's Follow-Up Surveillance program to ensure continued compliance and prevent unpleasant surprises when an end-product is inspected.

"Contemporary Controls was willing to secure and maintain UL 864 Recognition on the Ethernet switches," said Rule. "They had equipment configurations to meet our needs and they were able to provide local technical support."

Both the EIS eight-port copper Ethernet

switch and the EIS six-port copper/fiber optic unit met the following high-voltage testing levels:

- 6000 V supply line transients

- 2400 V signal circuit transients

- 5000 V input voltage surge

- 115% rated voltage overload

The

units can survive a temperature of 50°C

and 95° humidity for 24 hours and can operate

on a backup power source of 24 VDC supplied by the fire alarm panel.

The EIS8-100T provides eight 0/100 Mbps copper ports utilizing RJ-45 connectors.

The EIS6-100T/FT is a similar design but with only four copper ports and

two fiber optic ports utilizing ST connectors. The fiber optic units can

be deployed over long distances (up to 2 km) and in locations where high

noise immunity is desired. The switches offer wide range AC/DC operation.

But for this application, the switches only need to operate from low voltage

DC power. The units are mounted in a special enclosure that is also UL

Recognized for fire-protective signaling use. An MTBF of more than 40

years enable these units to be used with confidence.

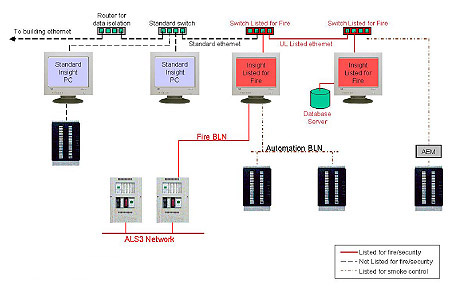

Using the APOGEE system, workstations communicating

over Ethernet can be positioned side-by-side or could be miles apart.

Additionally, a combination of Fire workstations, which are Listed for

protective-signaling use, and non-Fire workstations that are not, can

reside on the same network. The fire alarm system can only

be controlled from Fire workstations, but data can be monitored from

both Fire and non-Fire workstations.

Fire, security and automation systems can be managed from APOGEE Insight

workstations. The APOGEE system enables data from all connected systems

available to all workstations on the network. For greater efficiency,

a database server centrally administrates the networked system over

a Management Level Network (MLN) that sends information where it needs

to go without encumbering every workstation with unnecessary data.

Rule says users are assigned access privileges that dictate what they

can and can't observe. "This permits the flexibility for centralized

monitoring and/or widespread distribution of information."

UL Listed Fire workstations are typically located within the facility

or campus where the fire alarm system is installed; however, customers

often want the ability to monitor their systems remotely over the Internet

as well. APOGEE is flexible enough to provide this capability too.

Insight Life Safety workstations can be a part of a dedicated network

of Insight workstations or they can be part of a customer's enterprise

(or corporate) network. When connected to a corporate network, the Insight

workstations must reside on a dedicated IP subnet/ broadcast domain

isolated from the corporate network. Rule says this is accomplished

by using a router which prevents traffic from the corporate network

(i.e. broadcasts and other non-Insight messages) from interfering with

the ability for fire alarm signals to pass between Fire workstations.

He explains that this ensures all of the bandwidth on the dedicated

network is available for Insight communications. This configuration

increases data throughput and eliminates security issues that could

arise.

The system architecture locks together through the switches. Typically,

one switch is located at each Insight Fire Workstation on a Management

Level Network. A multiple of EIS8-100T's, connected by Category 5 cabling,

are employed when these workstations are short distances apart on the network-under 300 m. Segment lengths cannot exceed 100 m requiring

the use of multiple switches. The EIS6-100T/FT, for distances up to

2 km, provides interference-free fiber medium for connecting these workstations.

Typically one workstation is installed at the security desk so the operator

may take appropriate action to any life safety, security, or automation

related events. Copper or fiber connection to the next workstation is

determined by distance. The APOGEE workstations all reside on the Ethernet

network and serve the purpose of monitoring operation and annunciating

critical information. Ultimately, they are tied into the fire panels

via a Siemens proprietary network. In some facilities, 20 or more workstations

might be installed.

Rule says one workstation is often positioned for facilities maintenance

department use in order to ensure that maintenance has first hand knowledge

of any activations or faults on the fire alarm system. By having fire

alarm information available within their building automation management

system, the maintenance staff can immediately determine the precise

location of any problem and make adjustments as necessary. This eliminates

the need for security to communicate the need for action on

the fire alarm system to the facilities maintenance staff and expedites

the return to normal operation.

Additional workstations might also be installed at a facilities director's office or at critical points within the facility that are most effected by operation of various building systems. By having access to information from all building systems within a network of building management workstations, people associated with a facility can get access to the information they need, when and where they need it, to ensure the optimal performance of the facility.

Reliability was vital in this project because it is a life safety system. Siemens had to be assured that the life safety system would continue to function as intended, to save lives and minimize damage to the facility.

"By working with Contemporary Controls, we felt

confident that our life safety system would not fail us," says

Rule. "We

count on Contemporary Controls to provide reliable products and to have

parts and expertise available at all times."