Success Story

BAS Switch Used with ALC Controller at Data Center

In 2006, a Los Angeles, California data center underwent a a complete building controls retrofit for a premier colocation and data center management company headquartered in Denver, Colorado.Tthe data center spans 450,000 square feet over five floors, making it the ideal spot for high-density server applications. Diverse substations supplying high-voltage electricity combined with 16-foot ceilings and 150 lbs/square foot floor loading capacity will support the most demanding colocation applications.

Sunbelt Controls, the largest Automated Logic® Corporation (ALC) controls dealer in the western U.S, was chosen to complete the retrofit. Sunbelt Controls Project Manager/Sales Engineer Robert Grenader said the data center had been built in 2002, but the existing Direct Digital Control (DDC) system was left idle for years.

"The system was never commissioned after the dot.com bubble burst," Grenader explained. "I and my team of engineers realized the pressure was on for a complete system upgrade within a set timeline. The upgrade was necessary because devices from the existing system were no longer available and expansion was limited to the degree that it couldn't meet the needs of the new owner."

To accomplish this, Sunbelt Controls installed ALC's state-of-the art HVAC equipment and controls to improve maintenance and energy use. "We are monitoring more than 100 Computer Room Air Conditioner (CRAC) systems, 10 UPS systems, emergency generators, air-cooled chillers, roof-top cooling systems, electrical circuits, and overhead/underfloor leak detection systems," said Grenader. "ALC's system made it possible to interface over the customer's Ethernet LAN as well as various protocols including BACnet®/IP, BACnet via MS/TP, TCP/IP and ARCNET," said Grenader. "Two other benefits were ease of use and scalability."

Grenader said all the system traffic went through a consumer-grade, five-port Ethernet switch connected to the dedicated building automation server located in the facility's main computer room.

The switch was a problem. Periodically, it would lock up due to excessive packet collisions requiring a power down to be performed to restore communication. In addition, there wasn't a good method to install the switch in the control enclosures.

Grenader said they, "needed a dependable switch to handle the traffic load without hang-ups which is a problem if you're using consumer-grade hardware."

Sunbelt Controls chose to use Contemporary Controls' industrial-grade, five-port Ethernet switches because the the customer's LAN was Ethernet. "With the EIBA5-100T/R, we were able to take ALC system traffic onto the facility LAN, allowing us to take advantage of the gigabit backbone and remove traffic from our 156k ARCNET," said Grenader. The switch provided the functionality, DIN-rail mounting convenience and ruggedness to meet the needs of the data center.

Sunbelt Controls chose to use Contemporary Controls' industrial-grade, five-port Ethernet switches because the the customer's LAN was Ethernet. "With the EIBA5-100T/R, we were able to take ALC system traffic onto the facility LAN, allowing us to take advantage of the gigabit backbone and remove traffic from our 156k ARCNET," said Grenader. The switch provided the functionality, DIN-rail mounting convenience and ruggedness to meet the needs of the data center.

Sunbelt Controls was pleased with its $99 price tag and its compact size (measuring only 3.3" H x 3.5" W x 0.97" D). Engineers were able to mount it in a cabinet and operate it from the same source that powers other BAS equipment, making installation neat and secure. This device accepted 24 VAC for consistent power throughout the application and no extra wiring was required.

The LEDs on this unit faced the technician for easy network troubleshooting. The label on the device can be written upon so port connections can be documented as to the location of connected equipment. Built-in broadcast storm control prevented excessive broadcasts from degrading network performance. The product was designed to meet all regulatory standards including RoHS.

"In more than six months of operation, we have had no instance of this switch locking up due to excessive traffic," admitted Grenader. "That's far better than a consumer-grade product."

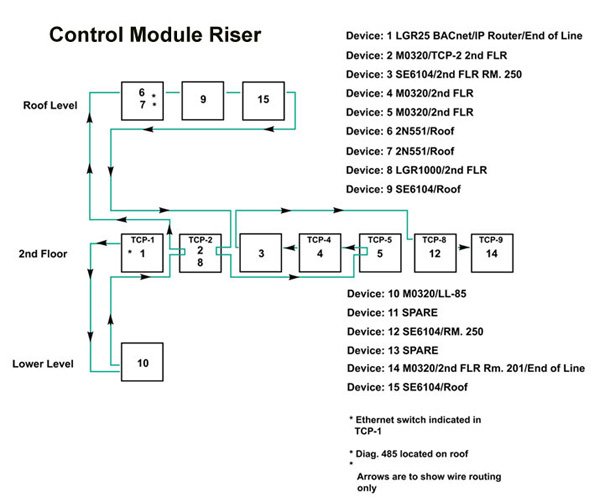

The switch is installed in a temperature control panel (TCP) located on the second floor among ALC's LGR high-speed Ethernet router and a Trane BCU with connection to the building automation server. The LGR connects the control modules to a BACnet/IP backbone. Designed with many benefits, the LGR router has the power to serve the most demanding translation and communications functions. CAT5 cabling from the EIBA5-100T/R to the LAN is less than 90 meters. Wiring routes from the first TCP to one M line (multi-equipment application) control module located on the lower level. The M line utilizes native BACnet communications over a high-speed ARCNET 156 Kbps network. The ARCNET limit is 2500 feet. The wiring travels from the M Line controller (on the lower level) to several control modules (enclosed in TCPs) including the S Line (single-equipment application) units on the second floor. The S line uses native BACnet communications to field devices over a high-speed BACnet MS/TP network. The wiring continues from the second floor to the roof level, connecting the zone controllers and other control modules. The zone controllers are for VAC, heat pump, unit ventilator and other packaged HV-ac applications. The wiring back loops from the roof level to the second floor of control modules to complete the network infrastructure.

All equipment was upgraded to ALC's WebCTRL® building automation system because of its excellent browser-based user interface and native BACnet open protocol. Through a browser anyone can access all building management functions including: set and change schedules, adjust setpoints and other control parameters, graphically trend important building conditions, run preconfigured and custom reports on energy usage and much more.

By pulling everyone's efforts together, the project was completed on time. Due to the much needed retrofit, the customer gained substantial savings. "The customer was finally able to access and monitor the critical data center equipment," said Grenader.